ColorSpan Belt

ColorSpan Belt

Price: $11.95 USD

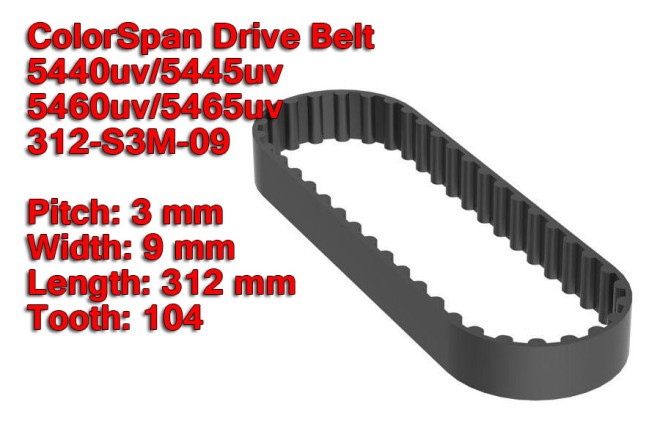

HP Scitex FB950 / Designjet H35100 / Designjet H35500 / Designjet H45100 / Designjet H45500 / ColorSpan 5440uv / ColorSpan 5445uv / ColorSpan 5460uv / ColorSpan 5465uv. This Drive Belt is suitable for HP Scitex FB950 printers. This is the original HP part (number CH971-91530). This closed belt has a length of 312mm, a width of 9mm

ColorSpan Belt

ColorSpan Belt

How to Install ColorSpan Beltadjust two screws that controls the tension on left side of the printer, have someone push your carriage from left to right slowly while you turning the screws to see if the Belt is aligned. you can say that its aligned if its not riding up and down. 4.6.2. Replacing the steel Belt Caution :When replacing the steel Belt, be careful not to cut your hands by the Belt. Notes : Do not damage the steel Belt. Remove following covers before replacing the steel Belt. Side cover R: refer to “Removing side cover R” Side cover L: refer to “Removing side cover L” Front cover: refer to “Removing the front cover” Carriage cover: refer to “Removing the carriage cover” Y rail cover: refer to “Removing the Y rail cover” Unlock the head. Notes : Refer to “Head Lock Menu” Move the carriage from the capping position to the left. Rotate the 2 steel ColorSpan Belt adjustment screws counterclockwisely to loosen the steel Belt. 1 = Steel Belt adjustment screws 2 = Steel Belt Remove the 2 screws fixing the steel Belt. 1 = Screws fixing the steel ColorSpan Belt 2 = Steel Belt Replace the steel Belt.Notes : Be careful when handling the steel Belt. The steel Belt may be cut off when accreting dust to it or creasing it. Reinstall all parts in the opposite order of the removal prColorSpandure. Perform steel ColorSpan Belt tension adjustment according to “Steel Belt tension adjustment”. Notes : Be careful when handling the steel Belt. The steel Belt may be cut off when accreting dust to it or creasing it. The driven pulley shaft is installed one way only. Refer to “Service Parts List/Exploded Views/Configuration Diagrams”, to install it correctly so that the bearing stoppers are on top. After installing the CR slave pulley assembly, move the carriage to the left and right manually to confirm that the steel Belt has been set equally in the center of the CR actuator pulley and the CR slave pulley assembly.

STEEL ColorSpan Belt TENSION ADJUSTMENT The prColorSpandure for adjusting the steel Belt tension is explained below. This section explains the prColorSpandure for adjusting steel Belt tension. When removing/installing the steel Belt, adjust its tension. Tools required for work: The following tools are required when adjusting the tension of the steel Belt. Tension gauge: max. 2.0 N (200 g) Steel Belt tension attachment 2: for gauge diameter 2mm (0.08in.) or less Notes : Refer to “jig and Tool list”. Adjustment PrColorSpandure Use the following prColorSpandure to adjust the tension of the steel Belt. Place the tension gauge at the center of the steel Belt. 1 = steel ColorSpan Belt 2 = Tension gauge. Notes : The regulation values for the tension of the steel ColorSpan Belt are shown below. 1. 50 inch, 64 inch specifications: 1.0 N +- 0.1 N (100 g +- 10 g) 2. 87 inch specifications: 0.9 N +- 0.1 N (90 g +- 10 g) If the tension of the steel ColorSpan Belt is not within the range of regulated values, adjust the steel Belt tension screws. 1 = Steel Belt 2 = Steel Belt tension screw 3 = CR slave pulley Move the CR cursor to the left and right once or twice. Adjust the CR driven pulley until the upper and lower margins are identical. Caution : If the tension is not equivalent across the entire ColorSpan Belt, it could snap during operation. buy ColorSpan steel belt www.LavaPrint.com

ColorSpan Belt

ColorSpan Belt

How to Install ColorSpan Beltadjust two screws that controls the tension on left side of the printer, have someone push your carriage from left to right slowly while you turning the screws to see if the Belt is aligned. you can say that its aligned if its not riding up and down. 4.6.2. Replacing the steel Belt Caution :When replacing the steel Belt, be careful not to cut your hands by the Belt. Notes : Do not damage the steel Belt. Remove following covers before replacing the steel Belt. Side cover R: refer to “Removing side cover R” Side cover L: refer to “Removing side cover L” Front cover: refer to “Removing the front cover” Carriage cover: refer to “Removing the carriage cover” Y rail cover: refer to “Removing the Y rail cover” Unlock the head. Notes : Refer to “Head Lock Menu” Move the carriage from the capping position to the left. Rotate the 2 steel ColorSpan Belt adjustment screws counterclockwisely to loosen the steel Belt. 1 = Steel Belt adjustment screws 2 = Steel Belt Remove the 2 screws fixing the steel Belt. 1 = Screws fixing the steel ColorSpan Belt 2 = Steel Belt Replace the steel Belt.Notes : Be careful when handling the steel Belt. The steel Belt may be cut off when accreting dust to it or creasing it. Reinstall all parts in the opposite order of the removal prColorSpandure. Perform steel ColorSpan Belt tension adjustment according to “Steel Belt tension adjustment”. Notes : Be careful when handling the steel Belt. The steel Belt may be cut off when accreting dust to it or creasing it. The driven pulley shaft is installed one way only. Refer to “Service Parts List/Exploded Views/Configuration Diagrams”, to install it correctly so that the bearing stoppers are on top. After installing the CR slave pulley assembly, move the carriage to the left and right manually to confirm that the steel Belt has been set equally in the center of the CR actuator pulley and the CR slave pulley assembly.

STEEL ColorSpan Belt TENSION ADJUSTMENT The prColorSpandure for adjusting the steel Belt tension is explained below. This section explains the prColorSpandure for adjusting steel Belt tension. When removing/installing the steel Belt, adjust its tension. Tools required for work: The following tools are required when adjusting the tension of the steel Belt. Tension gauge: max. 2.0 N (200 g) Steel Belt tension attachment 2: for gauge diameter 2mm (0.08in.) or less Notes : Refer to “jig and Tool list”. Adjustment PrColorSpandure Use the following prColorSpandure to adjust the tension of the steel Belt. Place the tension gauge at the center of the steel Belt. 1 = steel ColorSpan Belt 2 = Tension gauge. Notes : The regulation values for the tension of the steel ColorSpan Belt are shown below. 1. 50 inch, 64 inch specifications: 1.0 N +- 0.1 N (100 g +- 10 g) 2. 87 inch specifications: 0.9 N +- 0.1 N (90 g +- 10 g) If the tension of the steel ColorSpan Belt is not within the range of regulated values, adjust the steel Belt tension screws. 1 = Steel Belt 2 = Steel Belt tension screw 3 = CR slave pulley Move the CR cursor to the left and right once or twice. Adjust the CR driven pulley until the upper and lower margins are identical. Caution : If the tension is not equivalent across the entire ColorSpan Belt, it could snap during operation. buy ColorSpan steel belt www.LavaPrint.com